FBM Compatta tempering and enrobing machine Ideal for tempering, draining, dosing and enrobing. From 12’160.- chf HT For more information, please call our bakery and showroom sales office at: 021/732.17.16

Dimensions Description The COMPATTA tempering and coating machine is suitable for tempering, draining, dosing and coating. The continuous crystallization technology features two separate systems: heating by thermal induction to guarantee precision and reactivity, and cooling with gas, ensuring short lead times and precision in maintaining temperatures. LED signals indicate temperature changes (heating and crystallization) to monitor the progress of the crystallization cycle at all times, and an acoustic device signals arrival at the set temperature. A quick-release auger makes it possible to change the color of the chocolate without waste and in a very short time. The direction of rotation reverser allows chocolate to be emptied into the screw, reducing the time needed to restart the crystallization cycle. The machine is equipped with an electronic dosing unit with repetition and dosing time adjustment. Coating belt (on request) divisible into 2 parts with a total length of 1,360 mm, double chute coating hopper. Equipped with tapping device, independent motor for tail cutter, bearings and lever for paper roll stop, air diffuser with vertical adjustment. Technical data : Melt tank capacity: 15 kg LED signals Night cycle Electronic feeder with repeaters Auger dismantling device with automatic reverser Vibrating table Production capacity: from 75 Kg kg/hour Average consumption: KW 1.5 Voltage: 220V or 380 V 50 or 60 Hz three-phase or single-phase Weight: kg. 140 *Please note that this description has been automatically translated. *Prices are indicative only and may vary according to fluctuations in the euro exchange rate.

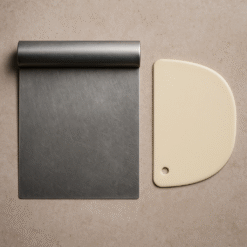

FBM Compatta tempering chocolate enrober